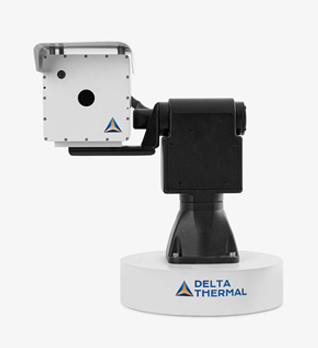

True Panoramic

Thermal Imaging

True Panoramic Thermal Imaging

Avoid hotspots, predict downtime, and eliminate outages with continual data. Our thermal monitoring systems track the temperature of various substation components. You’ll get an alert if the temperature

trendline increase beyond an acceptable threshold. This is far more efficient than outdated manual monitoring processes and keeps you informed in real-time.

Benefits of Our Thermal Monitoring Systems

Our substation monitoring systems offer a modern solution to replace inefficient monitoring practices that many substations are still employing. Some of the benefits include:

Instant Hotspot Detection

Predictive Analytics

Catastrophic Event Warning

Our products leverage thermography to automatically monitor and identify hotspots. Our systems monitor for hotspots 24/7/365. If there is an issue, you’ll get notified instantly. Knowing about a potential problem immediately is crucial, and infrared monitoring makes this possible.

Protect your perimeter and your reputation. Our system offers perimeter security and physical access control to protect against intruders. Like our infrared monitoring, you’ll get a real-time alert in case of any issue so that you and your team can address it immediately.

Our products leverage thermography to automatically monitor and identify hotspots. Our systems monitor for hotspots 24/7/365. If there is an issue, you'll get notified instantly. Knowing about a potential problem immediately is crucial, and infrared monitoring makes this possible.

Prevent catastrophes with predictive analytics that lets you foresee maintenance needs and downtime. While traditional monitoring with a thermal gun only gives you a snapshot of your system's health at one moment in time, our products continuously track temperatures and generate a trendline for predictive analysis.

Protect your perimeter and your reputation. Our system offers perimeter security and physical access control to protect against intruders. Like our infrared monitoring, you'll get a real-time alert in case of any issue so that you and your team can address it immediately.

“Delta Thermal helped us catch a potentially catastrophic weak point in our equipment that our normal routine missed. This system more than paid for itself the first year.”

Still relying on a thermal gun to check your substation status?

If you’re still sending someone with a thermal gun to your substation to monitor your equipment, you’re leaving the biggest job in protecting your business, community, and team to an archaic piece of equipment.

This standard maintenance gives you a snapshot into the current state of your equipment. Snapshot data tells you nothing about what is to come, what just occurred, or how you can be proactive for the future. It’s like settling for a polaroid when you could be accessing a movie worth of data.

With millions of dollars and potentially lives at stake in the event of a failure, choosing the best possible monitoring solution is critical. Our systems provide a modern solution for substation monitoring and allow you to avoid the limitations that come with using a thermal gun.

1999 Called.

They want their thermal gun back!

1999 Called.

They want their thermal gun back!

We Provide And Interpret The Heat Map Of Your Equipment

Real-Time Alerts

Easily Track Trendlines

Easily Track Trendlines

View Our Products

Real-time monitoring helps you avoid questions, like …

The Process of Setting Up Infrared Monitoring

Upgrade to 24/7/365 video feed with real-time, remote predictive monitoring. Protect your business, team, and community. Our products allow you to ditch the thermal gun, schedule downtime, and avoid explosive situations.

Ready to upgrade to some seriously smart monitoring?

Feasibility Assessment

Book a Site Visit

Share the Good News

Ready to upgrade to some seriously smart monitoring?

Let Us Do A Site Analysis And/Or Demo

Unlimited Applications For Protecting Your Value Chain

If you're wondering how Delta Thermal can help you, the first step is a feasibility assessment. We’ll answer all your questions and talk about your needs on our introductory phone call.

If we determine during the feasibility assessment that your substation would benefit from our infrared monitoring system, a team from Delta Thermal will come review your site and ensure proper set-up.

Once set-up is complete, you can enjoy the benefits of smart monitoring. Some of these include more data, safer substations, and a safer community. That’s good news you can share!

We Save Lives and Money

Make the Switch

to Delta Thermal

Your only downtime should be scheduled downtime. Stop settling for “snapshot data” that leaves you open to risks with long-lasting consequences. Retire the thermal gun and invest in the technology to protect what matters.